REBus: Pioneering resource efficient business models (REBMs)The need for transformational changePrecious resources are diminishing at a rapid rate globally. We consume three planet’s worth of raw materials – this cannot continue. European manufacturing firms already spend around 40% of their total costs on raw Enabling industry to changeREBus, an EU Life+ funded partnership project, is pioneering and testing a methodology that enables companies to transform their strategies to profitable, resilient and more resource efficient business models (REBMs). Delivering REBusWRAP and Dutch delivery partners Rijkswaterstaat (RWS) are supporting 30 SME’s, large businesses and government bodies to work through the REBM’s phases of: Suppliers process: Circular procurement process: The focus:

The sectors covered by this project are:

REBus is sharing the lessons learnt from these pilot projects through this website, case studies, a newsletter and at events across Europe. Other partnership roles:

|

Keeping products in use for longer

We have become a ‘throw-away’ society with many products ending up in landfill sites when they still have a re-usable value. At the end-of-life, many items could be recycled and precious materials extracted and re-used, especially from electrical and electronic products.

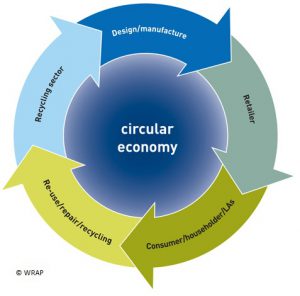

The current norm for linear business models, make – use – dispose, has to change .

The challenge is persuading businesses and procurers to take a leap of faith by presenting them with strong commercial business cases for implementing REBMs for supplying and procuring products.

REBM’s will enable businesses and procurers to contribute to a more circular economy. However, businesses are unlikely to change unless they can clearly understand the share of the value they can access. There needs to be a clear opportunity and REBus has helped companies and organisations recognise that opportunity through delivering REBM’s.

Evidence and business case for change

Please click on the images below to access further information: